- Production capacity, max. 1450

- Blown bottle volume, l. 3-6

- Bottle neck diameter, mm 48

- Number of places in the mold, pcs. 2

- Maximum bottle diameter, mm 180

- Maximum bottle height with neck, mm 350

The equipment allows to manufacture bottles of 3.0 to 6.0 liters capacity for bottling carbonated and still liquids.

The machine is equipped with pneumatic equipment made by leading manufacturers such as “FESTO”, “AirCom”, “SMC”, and “OMRON” controller and electronics.

| Parameter | Unit of measure | Parameter value |

| Bottle neck diameter | mm | 48 |

| Production capacity*, max. | bottles/h | 1200 – 1450** |

| – bottle capacity, | l | 5,0 |

| Blown bottle volume | l | 3,0-6,0 |

| Number of places in the mold | pcs. | 2 |

| Maximum bottle diameter | mm | 180 |

| Maximum bottle height with neck | mm | 350 |

| Pre-blowing pressure, max. | MPa | 1,0 |

| Blowing pressure | MPa | 2,5 |

| Control pressure | MPa | 0,8 |

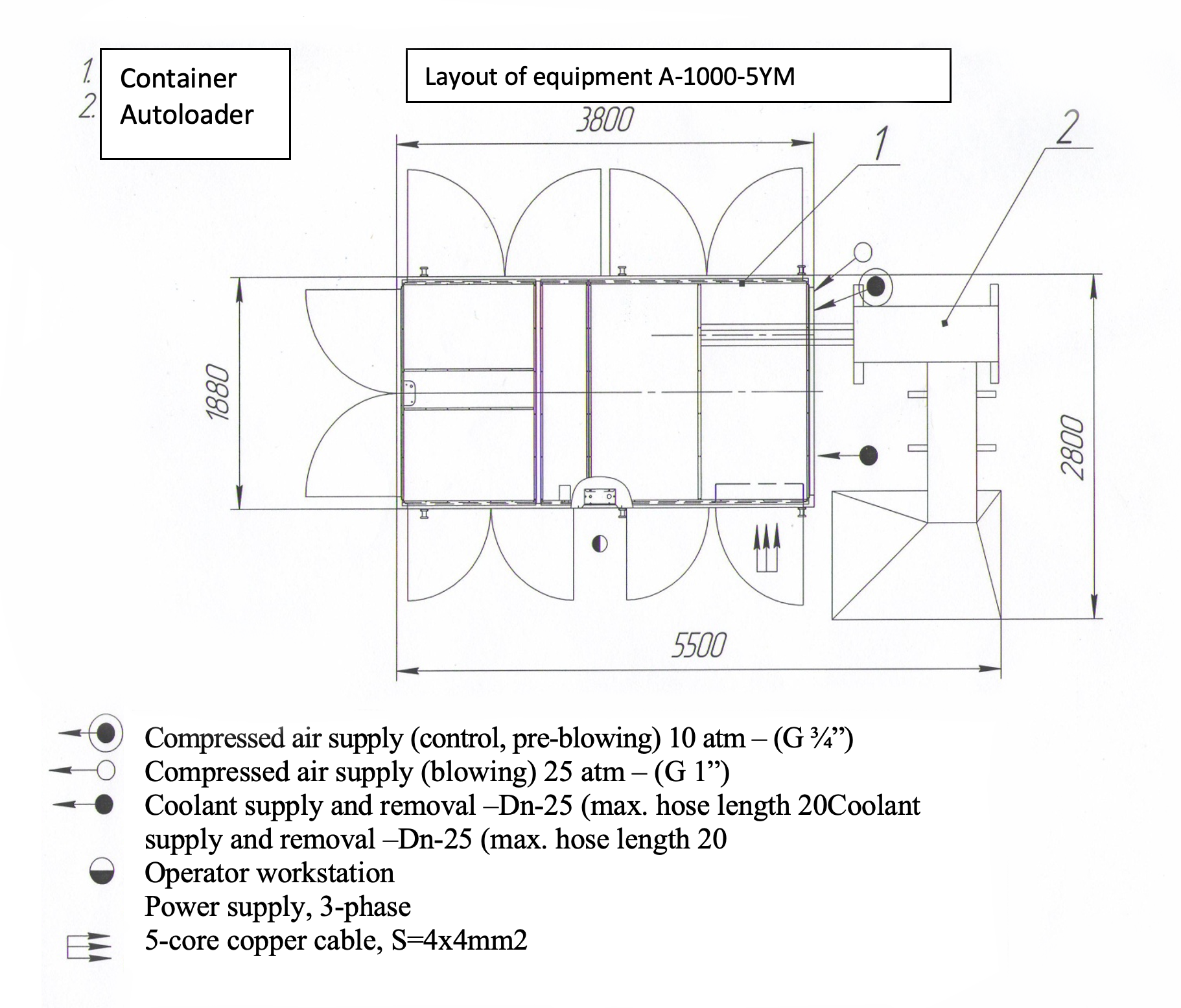

| Total compressed air consumption, including: | m3/min | 6,2 |

| – pre-blowing | m3/min | 1.5 /1.0 MPa/ |

| – blowing | m3/min | 2.53 /2.5 MPa/ |

| – control | m3/min | 1.45 /0.8 MPa/ |

| Coolant temperature | оС | 6-10 |

| Coolant flow rate | m3/h | 1,3 |

| Coolant pressure | MPa | 0,3 |

| Cooling capacity of the cooling unit | kW | 11,3 |

| Number of heating modules | pcs. | 21 |

| Number of heating zones | pcs. | 7 |

| Power consumption | kW | 17,5 |

| Supply voltage | V | 380 |

| Overall dimensions: | ||

| – length | mm | 6800 |

| – width | mm | 3200 |

| – height (by stretching rods) | mm | 2300 (2700) |

| – autoloader height | mm | 2600 |

| Total weight | kg | 4500 |

* Depending on the configuration and volume of blown PET bottles

** The manufacturer does not guarantee the established performance of the equipment when using molds from other manufacturers, non-compliance with the requirements for compressed air, cooling water, electrical connections, and industrial premise