AIR CONVEYORS

Air conveyor is designed for delivery ready packaging to different stages of the filling lines.

The air conveyor is an ideal means for transferring empty PET bottles, light bottles, due to the air flow, can be transported both horizontally and vertically, while gripping by the neck allows you to accurately fix the bottle in the filling unit, eliminating bottle distortion.

Advantages

Of Air

Conveyors

Reduced operating costs

System “soft start-stop”

High efficiency of cable lines

Preventing bottle jams

Reducing noise

The air conveyor is used to transport PET bottles from the blow molding machine to the filling machine, since the weight of the finished bottle is small and it is very unstable during gravitational transportation.

Typically, standard conveyors are designed for PET bottles with a neck diameter of no more than 112 mm, but if required, they can be equipped to transport bottles with a wider neck. Air pressure is provided by steel fans with multilayer air filters.

Compressed air is supplied along the guides to the transport compartment. Bottles suspended by the neck move in a given direction under the influence of the air flow pumped by the fan into the conveyor housing.

The converter and the motor can be separated by 100-150 meters. The use of a decentralized drive helps to significantly reduce the cost of installing equipment.

BELT CONVEYOR

Such a conveyor allows you to transport heavy items – full bottles and kegs.Additional equipment can be attached to the guard and the conveyor body – sensors, labeling machines (applicators), dating devices, etc

Advantages

Of Belt

Сonveyor

The possibility of transporting a wider (compared to belt conveyors) assortment of goods

The ability to transport goods along the route with steep ascents (up to 35°-45°, and with bucket-shaped plates – up to 65°-70°)

The possibility of transporting goods along a complex spatial trajectory

High reliability

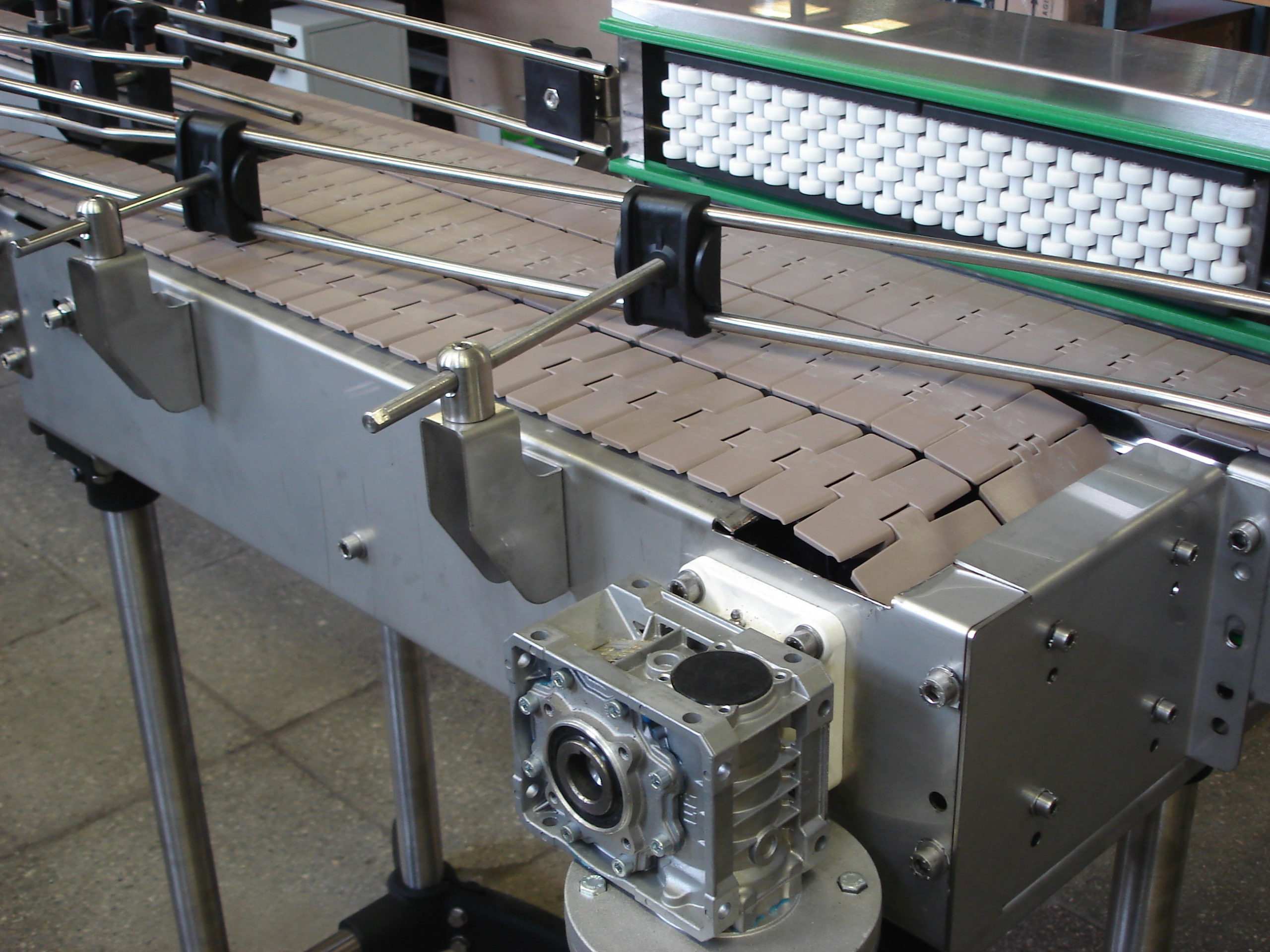

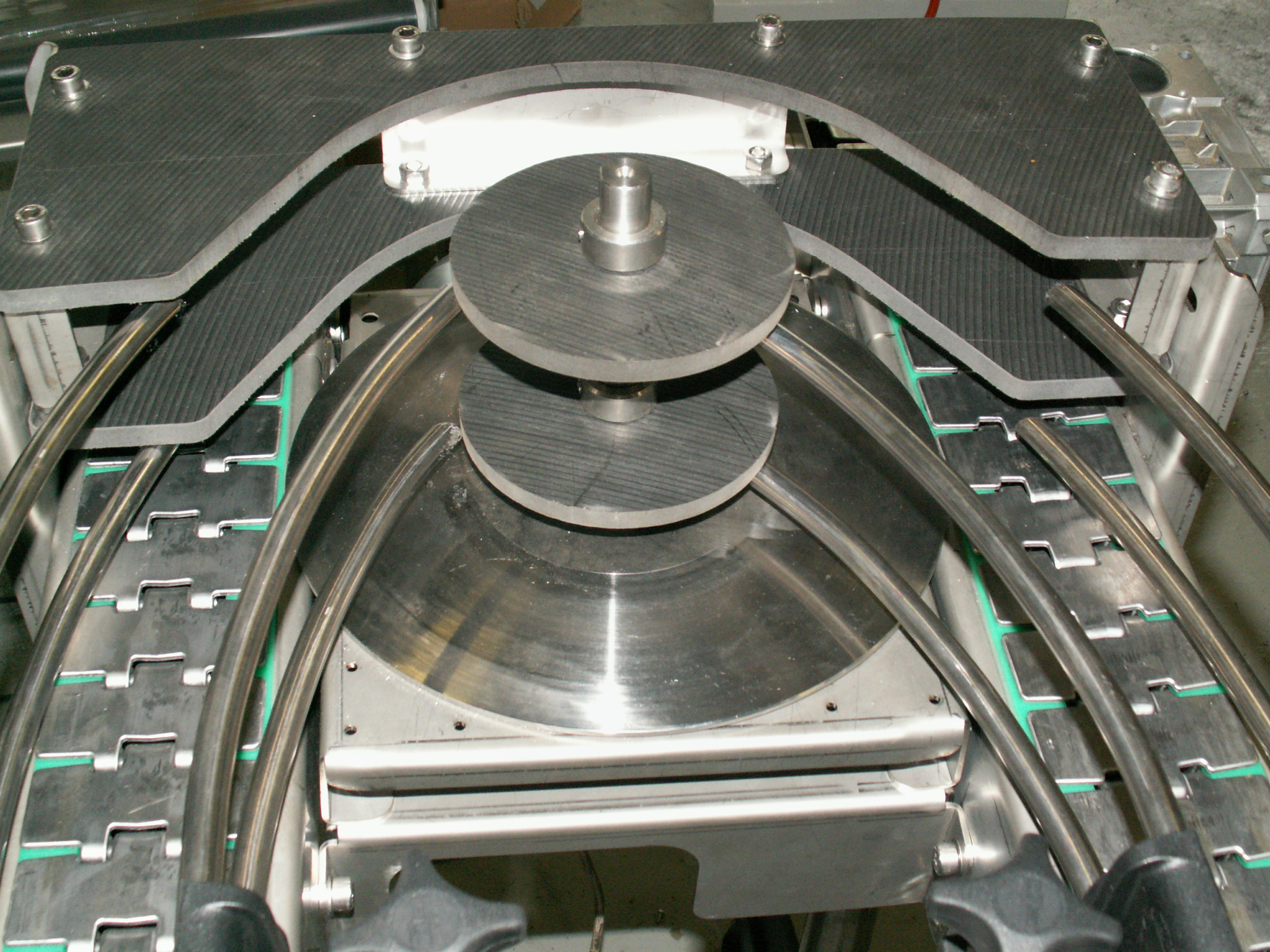

The belt conveyor consists of separate unified nodes, which allows you to change and add its configuration depending on the tasks.

Due to the versatility of the belt conveyor design, it has been widely used in various industries for moving piece and packaged goods.

All directions of routes used in belt conveyors are applicable to plate conveyors, respectively, horizontal, inclined or horizontally inclined routes are permissible. Horizontal bending of the conveyor is possible within a radius of 3-10 m.

The attached elements included in the design are manufactured both at leading European plants (AVE, Marbett, MCC, Rexnord, UNI, System Plast) and at our own production.

As a drive for plate conveyors, we use gear motors of various capacities manufactured by Vemat, SITI, Motive, Tramec (Italy). Speed control is carried out by means of a mechanical variator or frequency converter.